Over the last ten years it is obvious customers want things faster, better and more convenient. The foodservice industry is frantically trying to keep up with the constantly changing trends but gets slowed down by the day to day maintenance of the kitchen. Most foodservice owners/directors will agree for an industry revolving around the foodservice operations that the commercial equipment repair industry is anything but convenient. For restaurant owners/directors the most common frustrations can be…

At Clark Service Group we understand the importance of having things faster, better and more convenient. Here are the top ten reasons why Clark Service Group is truly the one-stop-shop of the commercial foodservice equipment service industry.

- Locating a local service company that will be available when emergency assistance is needed, not just regular business hours.

- Being forced to use multiple “specialty” service companies to repair the components of a commercial kitchen separately.

- Hiring a service company who claims to be the answer to every problem a restaurant could have only to find out you hired a “Jack-of-all-trades but master of none”.

- Realizing a service company does not have the man-power to keep up with the need of your location(s).

At Clark Service Group we understand the importance of having things faster, better and more convenient. Here are the top ten reasons why Clark Service Group is truly the one-stop-shop of the commercial foodservice equipment service industry.

- We service all commercial foodservice equipment. Gas/electric/hydro/etc.

- Cooking Equipment: Ranges, griddles, fryers, kettles, etc.

- Commercial Ovens: Convection, conveyor, microwaves, etc.

- Food Prep: Warmers, steamers, proofers, slicers, etc.

- Refrigeration: Walk-ins, reach-ins, display, portable, etc.

- Refrigerated units: Under-counter, prep tables, kegerators, etc.

- Beverage systems: Coffee machines, CO2 beverage dispensers, taps, etc.

- Ice machines: Water cooled, air cooled, under-counter, combinations, etc.

- Ware washing: Sinks, machines, water softeners, soap dispensers, etc.

- Unique units: Popcorn machines, cotton candy machines, hotdog roller grills, etc.

- We offer more than just a quick fix. After our technician has diagnosed the problematic equipment they will offer a full description of what they found. They will tell you what is broke, what it needs to start operating again, and what to do if it happens again or how to prevent it from happening at all.

- Do you have a brand new piece of equipment still under warranty but you have no clue how to properly file the paper work to keep it covered? Don’t worry; we can handle those warranty worries! We have a team of warranty specialist working with over 200 manufacturers to ensure your equipment stays covered.

- We carry over 1 million dollars in inventory of common break/replace equipment parts in our Lancaster warehouse! We have been in the foodservice equipment maintenance industry long enough to know waiting for parts to be shipped can prolong the repair of your equipment 7 to 10 business days!

- Trying to fix it yourself? Our customers can come in to pick up replacement parts when they need them. We have trained parts specialists that are ready and willing to help you find the parts you need.

- Out with the old; In with the new… We have a team of installation technicians that can install single unit replacements as well as full kitchen installations. They are capable of replacing walk-in cooler floors, foodservice counter-tops, seating, etc. They will also haul away the outdated piece(s) of equipment and debris.

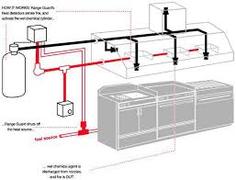

- Interested in proactive not reactive? We tailor our proactive maintenance programs to fit the needs of our customers. Whether you need all or just some pieces of equipment serviced monthly, quarterly, annually it’s up to you. We will clean filters, coils, etc., as well as give you professional technician advice about the equipment we are servicing.

- With over 40 service technicians working rotating schedules we offer round the clock service, 7 days a week 365 days a year (366 days on leap years). You can rest assure we will be ready and available for any emergency situation your facility may face!

- HVAC? Yes we can do that! No need to bring in another company to service your rooftop units. Our technicians are trained and equipped to safely service and repair all the components of your HVAC system.

- The last, but the most important, to Clark Service Group is providing unparalleled customer service in everything we do. We know the best way to grow as a company is build lasting relationships with our customers, based on integrity, quality and loyalty.

| Clark Service Group is a family owned business with over 40 years of experience serving the foodservice industry. Much like the foodservice industry, we have grown and evolved to better fit our customer’s needs. We understand convenience is no longer a luxury; it is a necessity. We pride ourselves on being a one-stop-shop for all your commercial foodservice equipment needs. We will continue to evaluate your needs and evolve to provide your foodservice establishment convenience and exceptional customer service. | |

RSS Feed

RSS Feed